Birthed in 1995, the concept of collaborative robots was part of a research project led by the General Motors Foundation. The foundation’s main aim was to create robots that were so safe they could work in collaboration with human beings. Now, about twenty three years later, cobots have not only found a place on the floors of numerous factories but are also a major trend in the world of robotics and technological developments of today. They are changing methods of operation especially in our automation, manufacturing and processing industries.

Out with the heavy and imposing traditional robots that stay locked in cages for our safety. It is time to pave way for collaborative robots. Cobots, unlike traditional robots are designed to work alongside humans, with them and not for them. However, even with their recent popularity, most people still don’t fully understand the difference between cobots and robots. Here are some of them.

Cobots have a partnership with human beings

Unlike traditional robots, cobots are designed to work collaboratively with humans just as the name suggests. With this new generation of robots you can say goodbye to cages or fences and hello to proper interaction.

Collaborative robots acts as assistants to human operators and are involved in targeted tasks that are sensitive and complex in nature and can’t be automated. In addition, cobots are well capable of learning. These robots have the ability to pick up objects and hand them over to humans in a more cooperative environment that is different from that of other industrial robots.

Cobots are teachable and flexible

Collaborative robots are quite easy to program. Some models of cobots are able to learn independently unlike traditional robot which need programming skills that are specialized. For instance, a technician can perform a movement with the arm of the robot thereafter, the robot can imitate and begin to reproduce automatically.

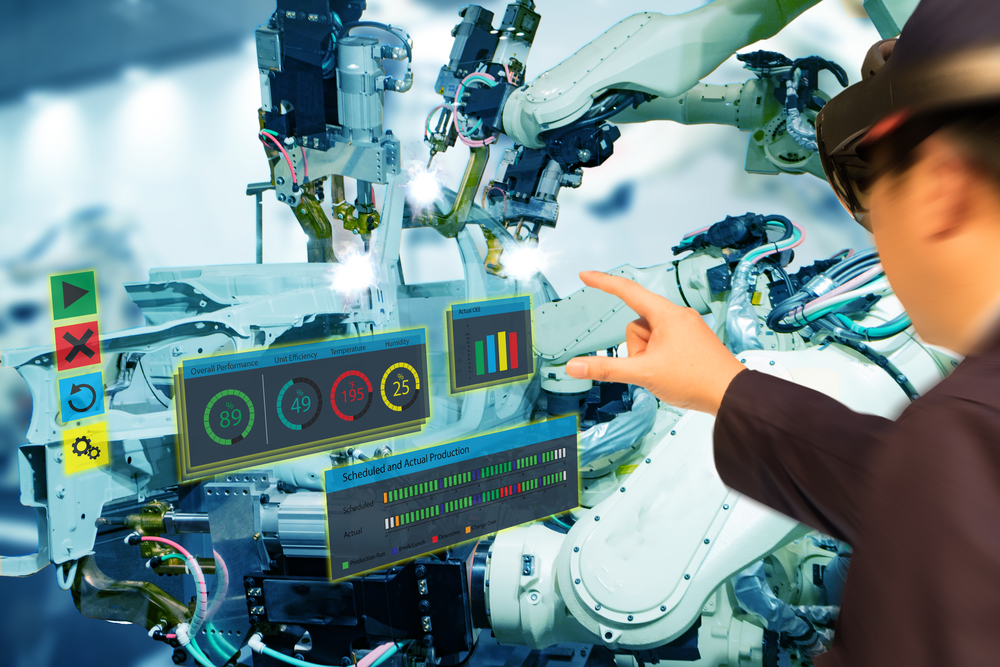

There are also other systems that can be given work instruction without the use of coding since they can simply take work instructions by the use of a graphic user interface. Therefore, employees can now flexibly program and reprogram collaborative robots and use them for a plethora of different tasks.

Cobots allow humans to concentrate on the core task of their business

Collaborative robots are tasked with the responsibility of safe handling tough, awkward or hot workpieces as well as low-added jobs in the workplace. For this reason, the human staff have all the time they need to focus on creating more added value to the business. This enables human intelligence to be refocused on other crucial aspect of the business and the chain of production.

Cobots are safe and they offer relief from risky tasks

Since collaborative robots can safely transfer dangerous bolting works, hot work pieces sharp or pointed objects, they get to fulfill tasks that would be naturally dangerous for humans. For this reason, there are far less accidents involved as compared to when the traditional industrial robots are involved.

Cobots are equipped with features that allow seamless collaboration between them and the human staff. Some models are equipped with detection sensor. This enable them to know where a human operator is at any given time. Some are also programmed to immediately stop working if the tasks they are performing poses any potential danger to a person near them. This eliminates the need for fences and cages.

Cobots can be used anywhere

Unlike traditional robots, collaborative robots can not only easy to program but they can also be moved and utilized at different points of the production chain. Most of them can be mounted on any surface either vertical, horizontal or on the ceiling. They are also light in terms of weight and can be moved from one place to another by just one person. This is not usually the case with traditional robots.

When deciding whether an industrial or collaborative robot is best suited for your business, there are many questions you need to ask yourself.